5/12/13

The Three Gorges Dam is a concrete gravity dam. The keyword is concrete. Concrete is made of a mixture of cement, sand, gravel, and water. Concrete was used in the construction of this dam, because of its mass, and its compressive abilities. Concrete is very strong under compression. Concrete can generally hold about 4,000 pounds per square inch under compression. However, while concrete is great under compression, it is not great under compression. It can hold about 400 pounds per square inch under tension. This is where steel comes in. Steel is also used in the construction of the Three Gorges Dam, because it reinforces the concrete in tension. Steel is strong in compression, but it is strong in tension. Also, concrete is cheaper than steel, so it is more logical to leave the responsibilities of compression to the concrete.

So how does steel reinforce concrete? There are steel reinforcing bars, or rebar, that are put together similar to cages, to set an area for the concrete to be dumped. The concrete is dumped on, and all around the rebar cages so that the steel is inside the concrete. There are four reasons why this strategy is so successful.

1. Concrete and steel have similar thermal properties that allow for the two to expand or contract uniformly. If they did not have similar thermal properties, the friction between the two would cause cracking.

2. The concrete and steel transfer stresses between the two very effectively. This strong bond is accredited to the ridges on the rebar that strengthens the bond.

3. The contact between the rebar and concrete forms a non-reactive surface, which prevents the rebar from corroding over time.

4. The rebar is excellent under tension, and can be used wherever the concrete needs reinforcement, especially at the bottom of the structure.

|

| Rebar Cage |

|

| Rebar Ridges |

Another very important concept to understand is heat of hydration. Hydration is the hardening of the concrete when the cement and water are mixed. This mixture is also an exothermic chemical reaction, which means that it gives off heat. Therefore, heat of hydration is the heat that is given off during the hardening or cooling of the concrete. The heat of hydration is a main factor in the laying of concrete and must be managed. If all the heat is not released, and there is a major drop in temperature, this can cause fracturing in the concrete, and lead to an unstable dam. Since the Three Gorges Dam is the biggest dam in the world, heat of hydration was a major concern. However, this concern was managed effectively and efficiently. Ice chips were put in with the concrete to reduce the temperature given off during the reaction. Very thin pipes were also constructed in with the concrete, and cold water was run through the pipes. This allowed the heat to be transferred into the pipes, and then the water was dumped right out of the concrete. The pipes were only temporary, but they were in the concrete for years, because it takes a long time for that much concrete to effectively cool.

Another process that is used to make effective concrete is air-entrainment. This process is when very small air bubbles are dispersed throughout the concrete. Having multiple tiny air bubbles spread through out the concrete makes it stronger, because it allows the concrete to expand and contract due to thermal effects. It also prevents the formation of large air bubbles that could cause cracking and fracturing when too much weight is put on it. Concrete is air-entertained by adding organic substances to it such as animal or wood-byproducts. These additions increase the freeze-thaw resistance, and makes the concrete more workable.

By: Matthew Cimino

References:

http://www.constructionknowledge.net/concrete/concrete_basics.php

http://www.concreteideas.com/concrete-basics-heat-of-hydration

http://www.cv.titech.ac.jp/~courses/atce2/dam.pdf

http://factoring.qlfs.com/blog/2010/05/03/selling-steel-reinforcing-bars-rebar-learn-how-factoring-can-help-you-grow/

https://beta.whitecap.com/pages/articles/rebar/federal-standards-rebar-couplers

http://www.fhwa.dot.gov/infrastructure/materialsgrp/airentr.htm

5/7/13

The Three Gorges Dam is a massive concrete gravity dam. Concrete gravity dams are defined to be dams that use the force of gravity as the main force holding back the water. The dam uses gravity to keep its mass from being tipped over by the pressure of the water, or from being pushed downstream. The Three Gorges Dam, like most gravity dams, are made out of concrete and steel. The steel is used to set the foundation of the dam, while layer upon layer of concrete is laid to construct the dam. This concrete is made out of cement, water, and some kind of stone. In the case of the Three Gorges Dam, sand rock was used to mix the concrete. Concrete is used, because it is waterproof and extremely strong and heavy.

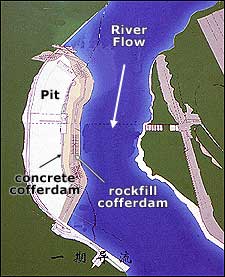

Yet before any concrete can be laid, the foundation has to be set. The construction of the dam was divided into three phases. The purpose of the first phase was to divert the river away from the construction of part of the dam. This was done by dumping large amounts of rock into the river to form cofferdams, which are temporary dams that are used to diverge water, and dry out an area. Two rock-cofferdams were dumped into the river, one upstream of the dam, and one downstream of the dam. A concrete cofferdam was constructed between the two rock-cofferdams to form an area between the bank and the three cofferdams. All the water was then pumped out of this area to create a dry pit. This pit was also dug out, so that the river could be easily diverged.

|

| Phase 1 http://www.britishdams.org/about_dams/3gorges.htm |

|

| Phase 2 http://www.britishdams.org/about_dams/3gorges.htm

|

Phase 3 is the last and final step in the construction of the dam. Two rock-cofferdams were placed in similar positions in Phase 1 to divert the water towards the main part of the Three Gorges Dam that was constructed in Phase 2. This area was then pumped free of the water, and the final part of the dam was constructed.

Phase 3

More information about the actual laying of concrete, and construction of the boat locks to come soon.

By: Matthew Cimino